Stainless steel vacuum water bottles are an important part of promotional items, for the simple reason that we can’t live without water every day. Using the customized water bottles allow your customer to be close with your product, and the fact that they are having repeated exposure to your brand is a bonus. So, how to customize high-quality Stainless steel vacuum water bottles?

#1. Material

First, we will analyze the material of the stainless steel vacuum water bottle. stainless steel comes in three main categories: 200 Series, 300 Series, and 400 Series, the most common 300 Series steel in the stainless steel vacuum water bottle is 304 stainless & 201 stainless. So, what’s the difference between SS304 and SS201?

In short, the biggest difference between them is the difference in nickel content. 304 stainless steel contains 18% chromium and 9% nickel in standard, and 201 stainless steel contains 15% chromium and 5% nickel. The higher the nickel content, the more resistant the stainless steel is to corrosion. In addition, 304 Stainless Steel is FDA approved. It is also American National Standards Institute (ANSI) and National Science Foundation (NSF) approved for food contact. So, we often use 304 stainless steel for the inner liner of the bottle. This is also one of the criteria to judge the quality of stainless steel vacuum water bottles.

#2. Insulation performance

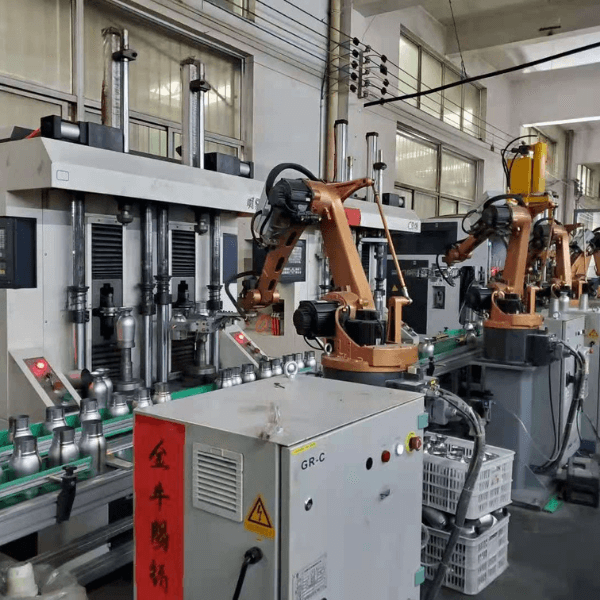

Next, we will consider the most important point of Stainless steel vacuum water bottles – insulation performance. As we all know, stainless steel vacuum water bottles are made of Stainless Steel and with Double Walls, it will make your thermos features an insulating layer between the two inner stainless steel. Together, these design elements keep your coffee cold or hot. Therefore, in the process of making stainless steel vacuum bottles, it is especially important if the cups are kept sealed. There are basically two different ways to make stainless steel into the shape of a bottle: water expansion and stretching.

Water expansion process

Stainless steel pipes as material. First, a stainless steel pipe is cut at the appropriate length, and a large amount of water is injected into the pipe. Then, the pipe swells into a bottle shape under the huge pressure of the water. Finally, a round stainless steel plate will be welded onto it to form a complete bottle.

Stretch process

in this method, stainless steel sheets are used as material. First, the stainless steel sheets are cut into round plates, and then we use a punch press to stretch the stainless steel plate into a cylinder with a bottom.

In my experience, I personally prefer the water expansion production process.

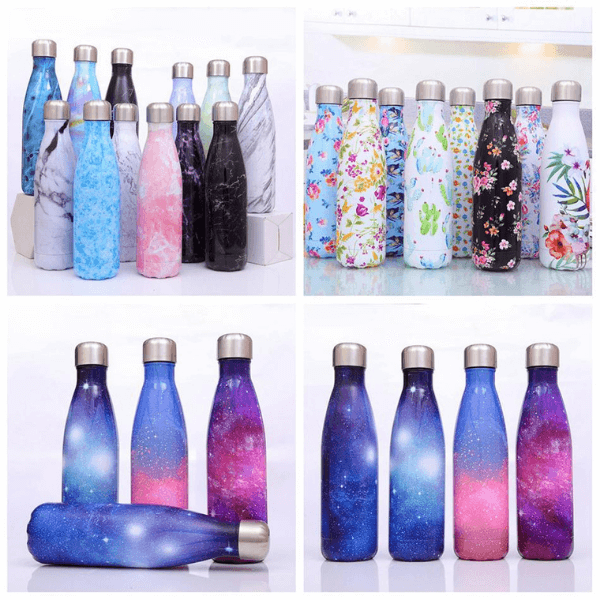

#3. Printing

Any promotional products are inevitable in their surface printing patterns or logos, of course, including stainless steel vacuum water bottles. The following 3 types of conventional printing methods are available:

Thermal transfer

Thermal transfer technology has long been used in the production of fabric thermal transfer printing. With the rapid development of high technology, thermal transfer technology is more and more widely used. The thermal transfer printing process of stainless steel vacuum flask is already a mature thermal transfer technology at the stainless steel water bottle factory. Compared with screen printing, heat transfer printing is more complicated. If you need a customized LOGO with 3 or more colors, or even with gradients.

Screen Printing

Screen printing is a common printing method at present. It is suitable for almost all materials (such as plastic, stainless steel, glass, silica gel, etc.). And its MOQ is relatively low, generally, more than 500 pcs could be customized LOGO with screen printing.

Water transfer printing

Water transfer printing consists of dipping an item into a large vat of water. It’s necessary to have transfer film displaying the design you want to transfer. This film then gets floated in a vat (tank or tub) of water (of appropriate size) and dissolves with the help of an activator chemical leaving only the ink behind with its polyvinyl alcohol backing.

Water transfer printing is the most suitable for printing on stainless steel vacuum water bottles among the above three printing methods. This method not only can print complex graphics, most importantly, it is very suitable for irregular-shaped objects, of course, it is obvious that this printing method is also more expensive.

For more information on how to custom print logos on promotional items, please refer to my other article – How to customize logo on promotional items? Attached are the links to the articles as follows: